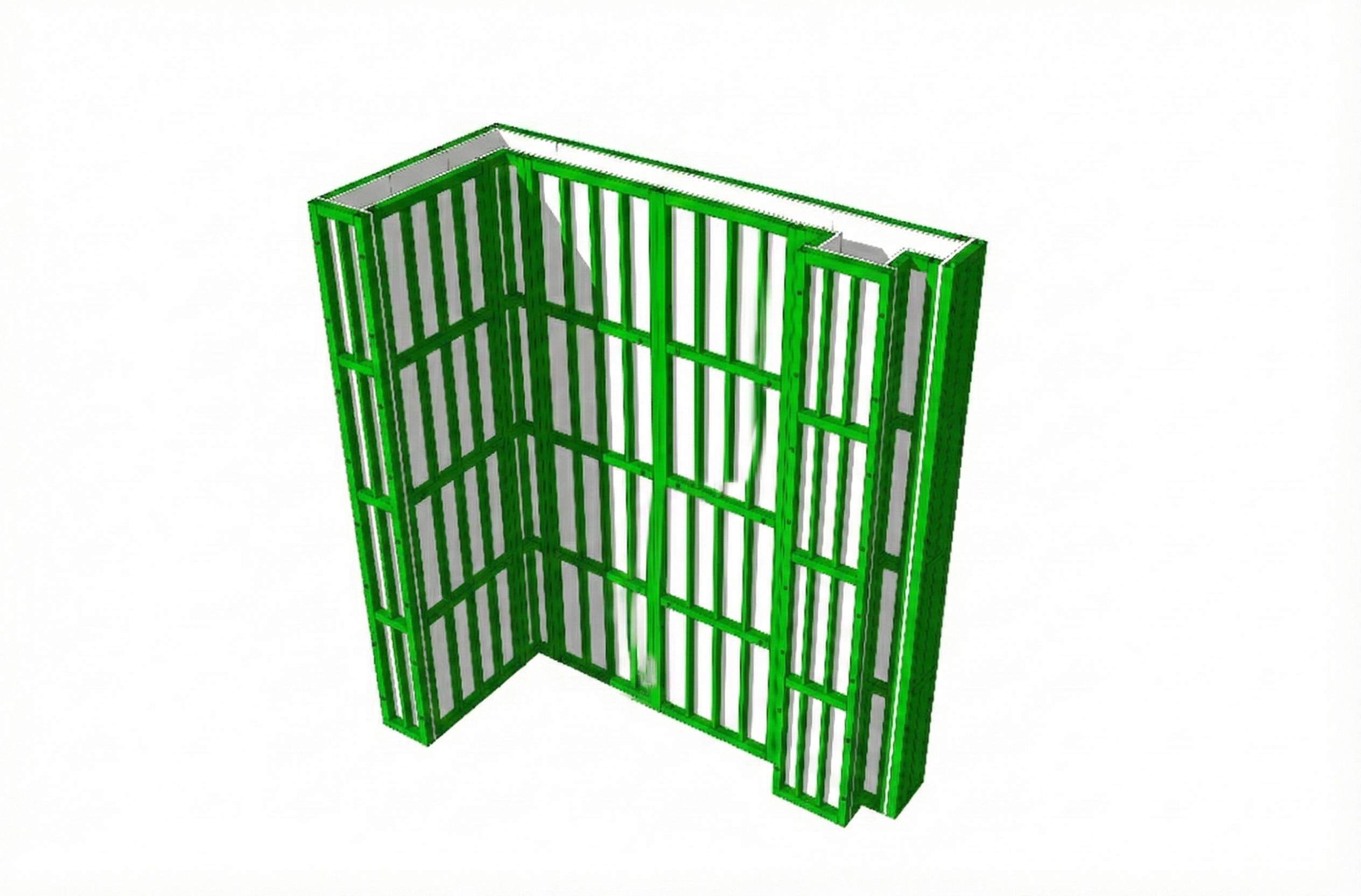

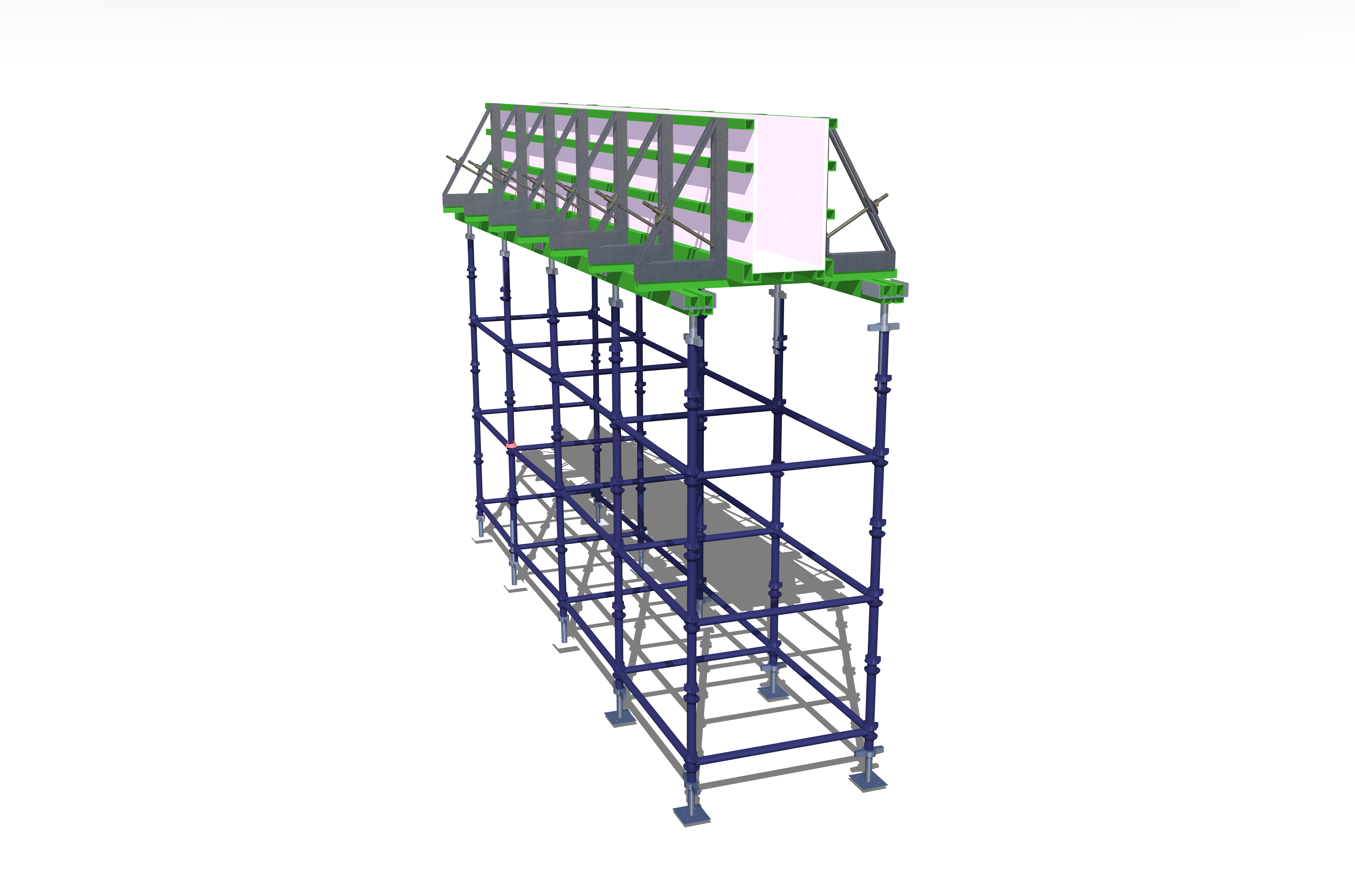

About Wall Formwork Systems

Wall formwork is a specialized construction system that creates temporary molds for casting reinforced concrete walls. NexGen's steel-reinforced PP wall formwork delivers exceptional strength, precision, and versatility for all types of vertical structures—from retaining walls to lift shafts. Our modular panel system withstands concrete pressures up to 60 kN/m² while maintaining dimensional accuracy and smooth finishes, reducing finishing costs by 35-45%.

Key Benefits

60 kN/m² Pressure

Handles high concrete pressure safely

100+ Reuse Cycles

Maximum ROI with extended lifespan

Multiple Panel Sizes

Multiple panel sizes for any wall

Quick Assembly

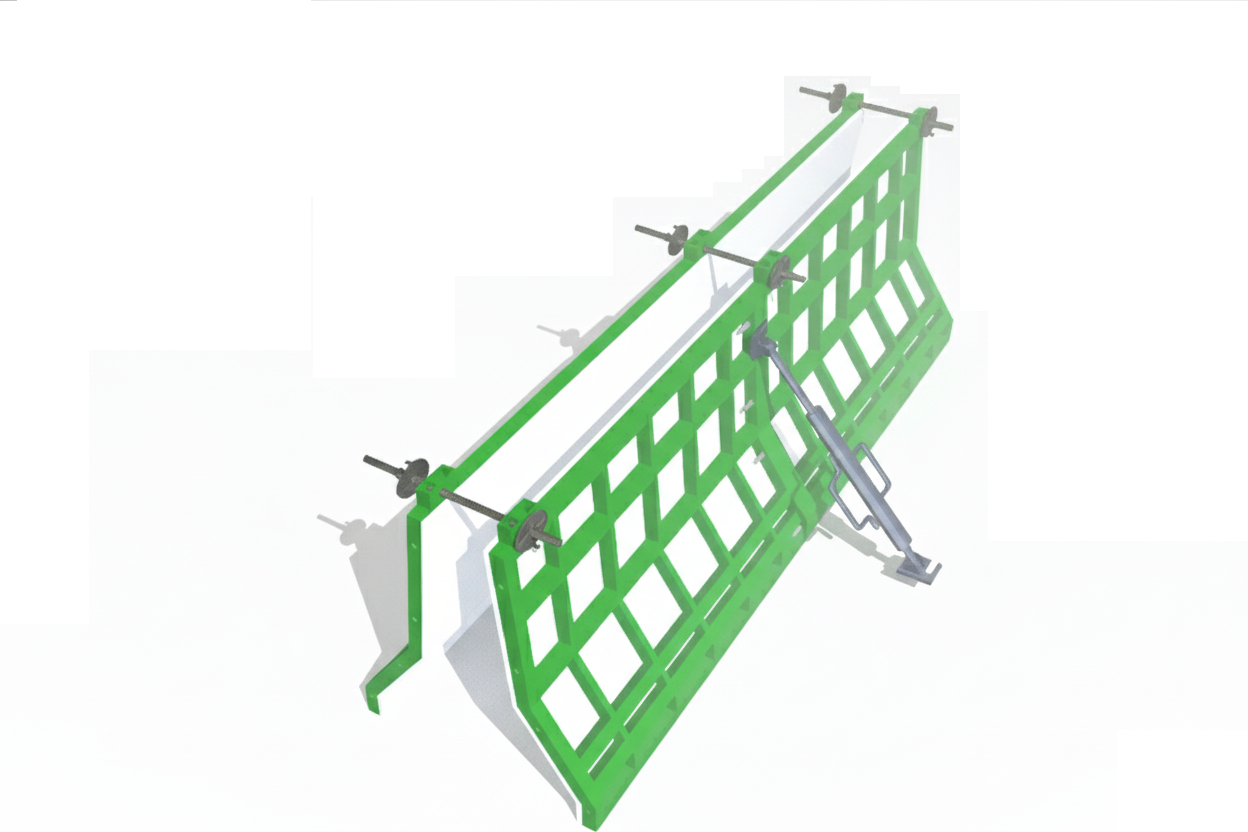

Quick pin-and-wedge connection