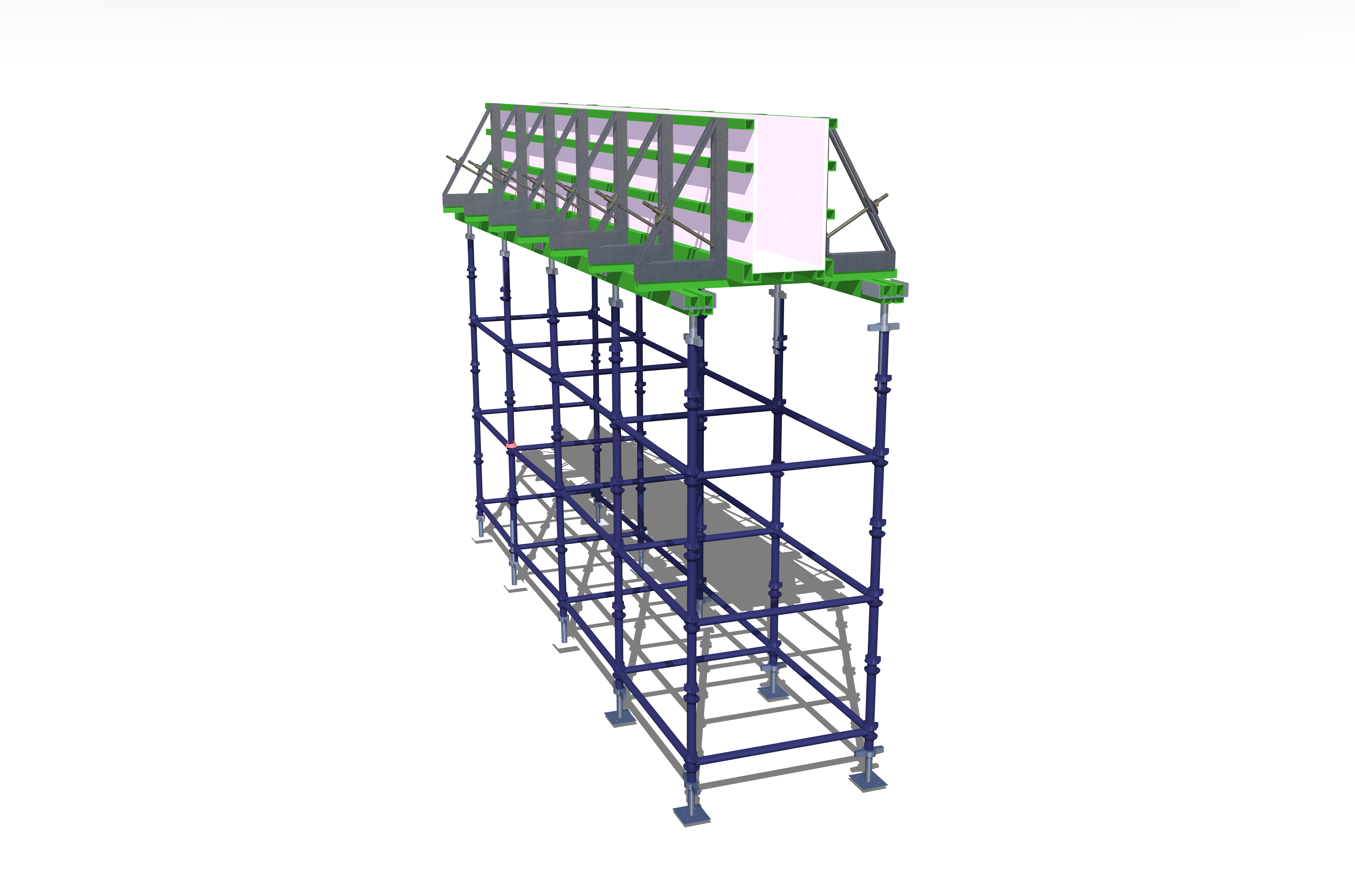

About Slab Formwork Systems

Slab formwork is a specialized horizontal forming system designed for casting reinforced concrete slabs, floors, and roof decks. NexGen's modular panel system with integrated drop heads enables early stripping, reducing cycle times by up to 40%. Our lightweight design (18-22 kg/m²) with steel beams and PP panels provides superior flexibility for any slab thickness from 100mm to 500mm, covering applications from residential buildings to multi-story commercial structures.

Key Benefits

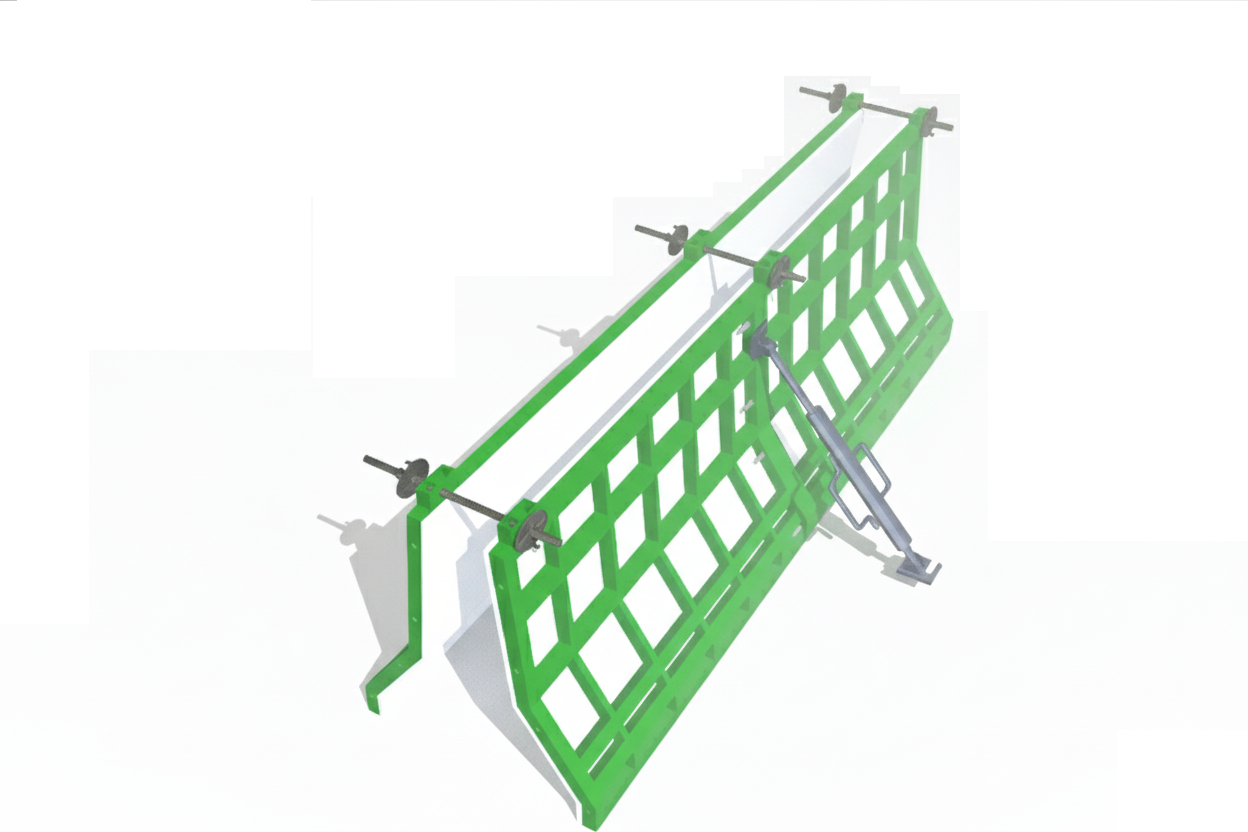

Early Stripping

Drop head technology for 66% faster cycling

Modular Flexibility

Adapts to any slab layout and thickness

Lightweight Design

18-22 kg/m² - easy manual handling

Prop Integration

Compatible with all prop systems