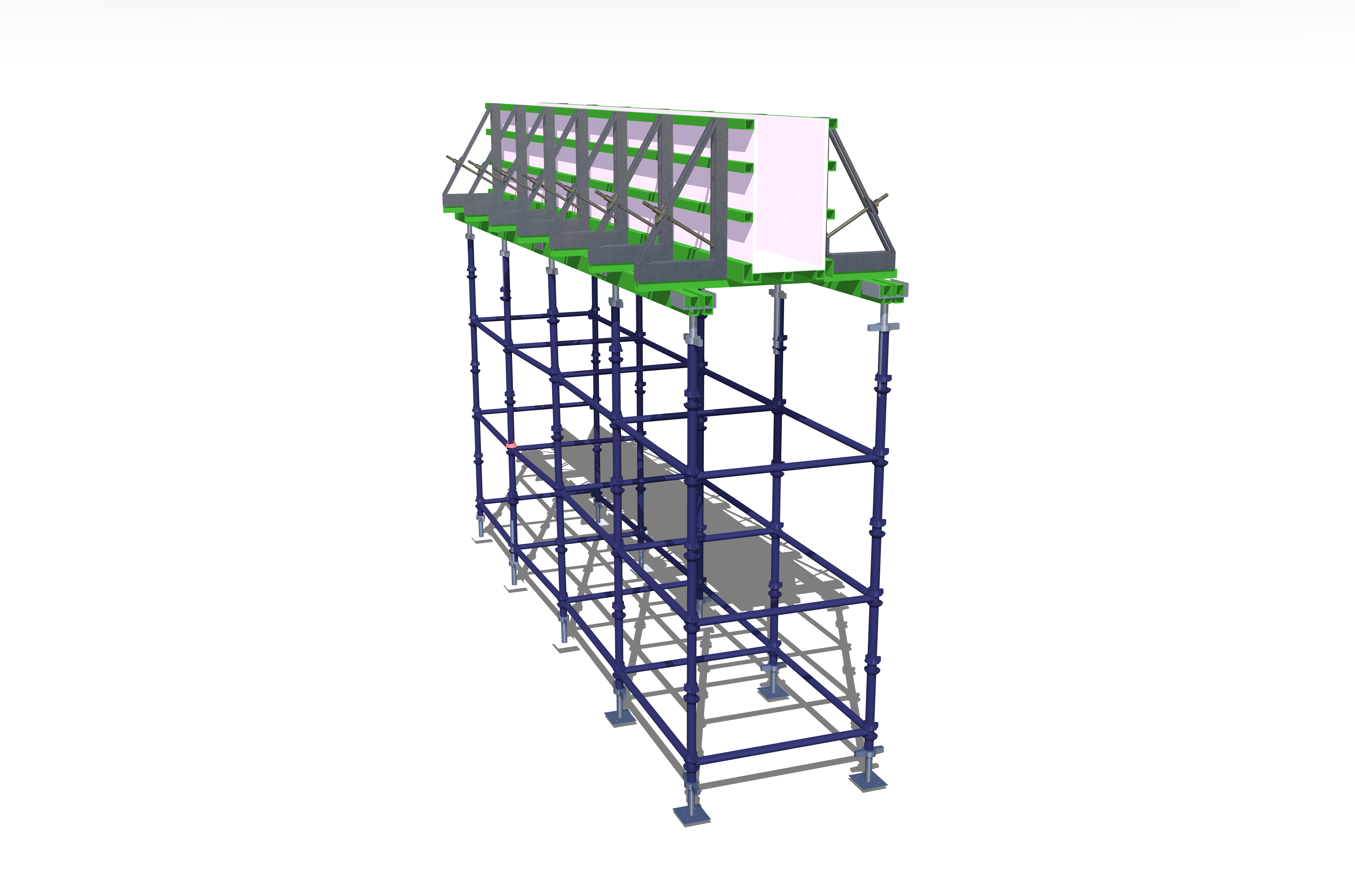

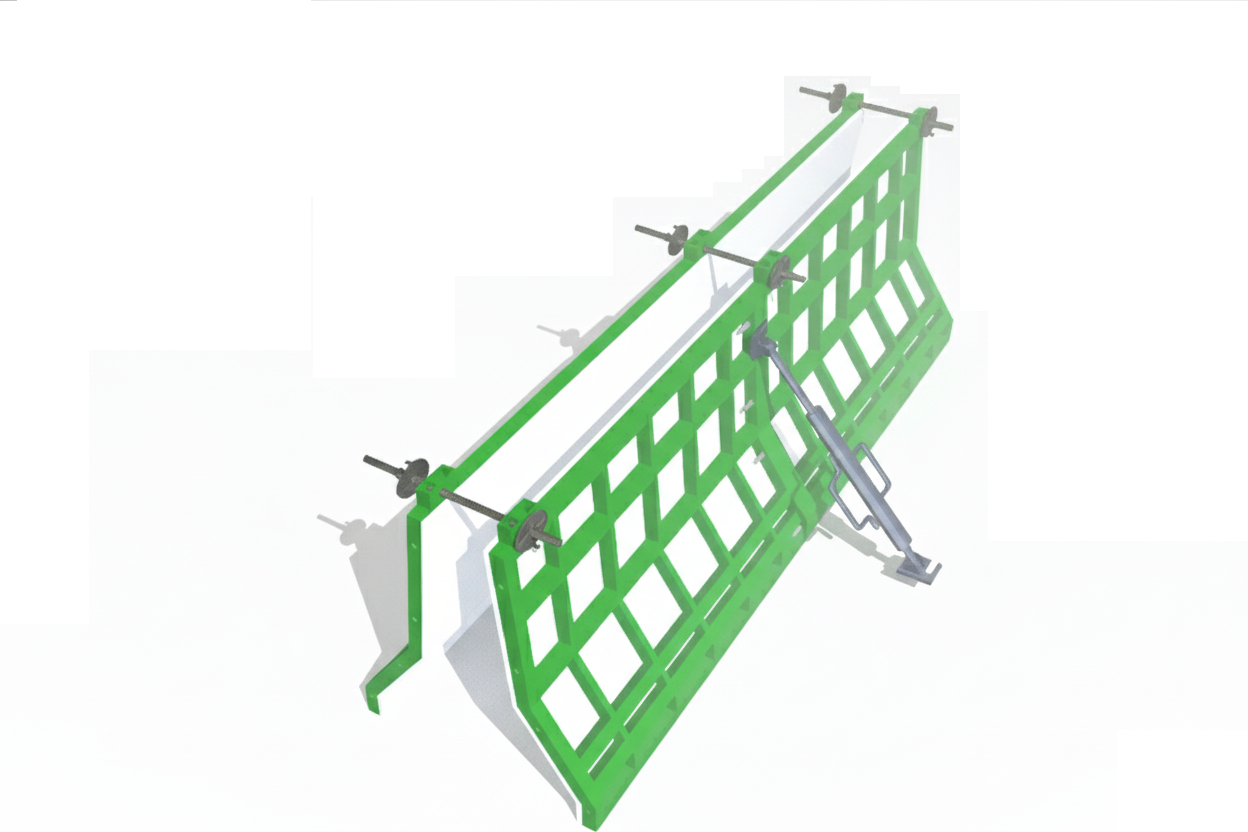

About Column Formwork

Column formwork is engineered concrete shuttering that creates temporary molds for casting reinforced concrete columns. NexGen's steel-reinforced PP formwork delivers precision, durability, and cost savings unmatched by traditional wooden systems. Built for rectangular, square, and circular columns—any size, any shape—our systems guarantee ±1mm dimensional accuracy and smooth concrete finishes.

Key Benefits

100+ Reuse Cycles

Maximizes ROI with extended lifespan

±1mm Precision

Perfect dimensional accuracy

Lightweight

50% lighter than steel formwork

Eco-Friendly

100% recyclable materials